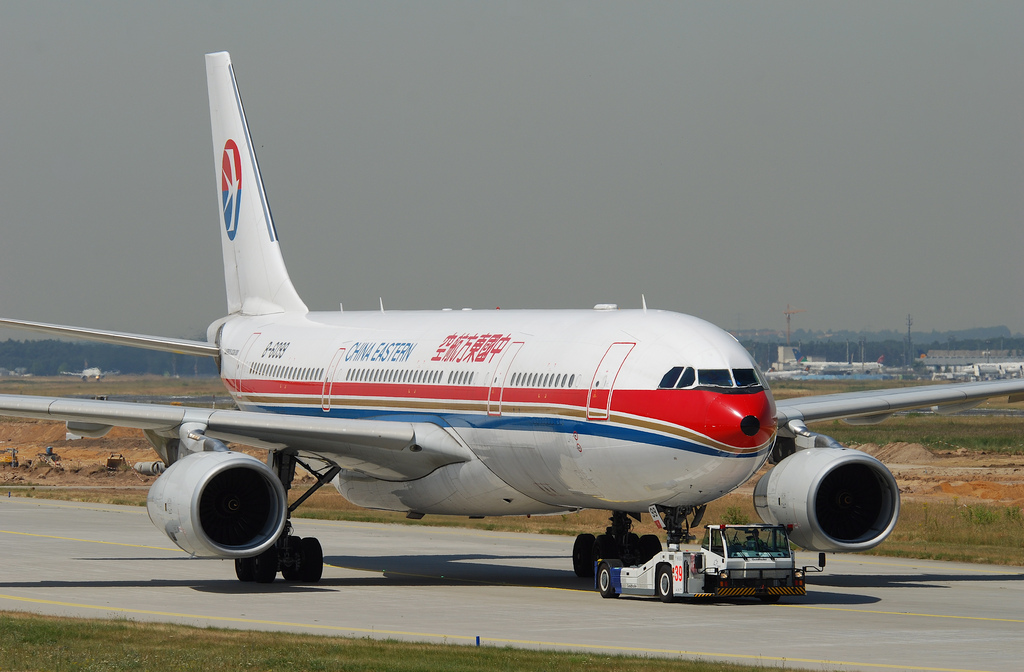

China Eastern A332 at Sydney on Jun 11th 2017, engine cowling malfunction

Last Update: November 20, 2019 / 15:08:26 GMT/Zulu time

Incident Facts

Date of incident

Jun 11, 2017

Classification

Incident

Airline

China Eastern Airlines

Flight number

MU-736

Departure

Sydney, Australia

Destination

Shanghai Pudong, China

Aircraft Registration

B-6099

Aircraft Type

Airbus A330-200

ICAO Type Designator

A332

On Jun 13th 2017 the ATSB reported that during takeoff a section of the left engine inlet separated from the aircraft. The crew dumped fuel and returned to Sydney. There were no injuries. The occurrence was rated a serious incident and is being investigated by the ATSB. The investigation is estimated to conclude not before June 2018.

A seemingly similiar incident also involving a Trent 772 engine happened about 4 weeks ago, see Incident: Egypt A332 at Cairo on May 15th 2017, rejected takeoff due to engine failure.

Possibly related there may be two Airworthiness Directives released by EASA, see 2011-0173R1 of Aug 21st 2014 and 2016-0086R1 of May 13th 2016.

AD 2011-0173R1 reasons: "Two operators of A330 aeroplanes fitted with Rolls-Royce Trent 700 engines reported finding extensive damage to engine air intake cowls as a result of acoustic panel collapse, most probably caused by panel disbonding. This condition, if not detected and corrected, could lead to the detachment of the engine air intake cowl from the engine, possibly resulting in ingestion of parts by, and consequence damage to, the engine, or injury to persons on the ground."

AD 2016-0086R1 reasons: "During shop visit, cracks were found in several primary structural parts of Rolls Royce (RR) Trent 700 engine air intake cowls, specifically in the forward bulkhead web, web stiffeners and outer boundary angles (OBA). In addition, several attachment links were found severely worn, and some became detached. In two cases, the thermal anti- ice (TAI) piccolo tube was found fractured. Investigation results show that the cracks are most likely due to acoustic excitation and vibration. A broken piccolo tube, if not detected and corrected, in conjunction with forward air intake cowl bulkhead damage, could lead to in-flight detachment of the outer barrel, possibly resulting in damage to the engine or reduced control of the aeroplane."

On Nov 20th 2019 the ATSB released their final report concluding the probable cause of the incident was:

From the evidence available, the following findings are made with respect to the failure of the left engine inlet cowling fitted to China Eastern Airlines Airbus A330-200 aircraft, registered B-6099 that occurred on 11 June 2017 during take-off from Sydney Airport, New South Wales. These findings should not be read as apportioning blame or liability to any particular organisation or individual.

Contributing factors

- During take-off, one of the three acoustic panels and the inboard outer skin of the left engine inlet cowling separated and were ingested into the engine. The engine sustained damage and the aircraft returned to the departure airport.

Other Key findings

- The ATSB and the engine manufacturer, Rolls-Royce, were unable to determine conclusively the reason for the acoustic panel failure.

The ATSB reported that according to the FDR the left EPR began to decrease at the time of rotation for takeoff, at the same time the N1 speed increased into an overspeed condition and N1 vibrations increased temporarily for one second. The engine however continued to produce thrust. The aircraft climbed out, at 5000 feet the crew declared PAN PAN and reduced the engine to idle. The aircraft burned off fuel and returned to Sydney.

The ATSB wrote: "The aircraft was taxied to the terminal where passengers disembarked and maintenance engineers inspected the aircraft. Damage to the left engine inlet cowling was identified, including the No. 1 and No. 3 acoustic panels, and the inboard side outer inlet cowling skin. In addition, substantial damage was identified to the left engine fan blades and the cold stream duct.5 Minor airframe damage to the left wing trailing edge flaps, landing gear door, and left side of the horizontal stabiliser was also identified."

The ATSB reported the engine inlet cowling is manufactured by Bombardier Aerospace on behalf of Rolls Royce. The ATSB wrote:

The damaged inlet cowling (serial number 1530) fitted to the left engine of B-6099 was manufactured during January 2008. At the time of the incident, it had operated for a total of 41,023 hours and 8,051 cycles. The inlet cowling had been inspected for delamination ‘on-wing’ four times since the introduction of Rolls-Royce service bulletin (SB) RB 211-71-AG419. The most recent inspection was performed in March 2017, in a United States Federal Aviation Administration (FAA) approved facility in China. During that inspection, nil delamination was identified on the incident panels.

During the inspection following the incident, it was identified that the adjacent acoustic panel (No. 2), that did not fail, had three local acoustic lining repairs. This indicated that the method used to inspect the panels ‘on-wing’ resulted in past repairs. Therefore, it is reasonable to conclude that the inspection method to identify delamination was likely an effective technique.

The ATSB analysed the causes of the failure of the acoustic panels:

The acoustic panels on the Trent 700 engines were manufactured by Bombardier Aerospace on behalf of Rolls-Royce. The panels fitted to B-6099 were constructed from a 3/4 inch honeycomb cell, 1.5 lbs/ft3 density honeycomb core.

Extensive testing was conducted. Rolls-Royce and Bombardier Aerospace considered that the failure was most likely due to a localised disbond between the facing sheet and honeycomb core. However, as the majority of the panel was ingested into the engine, there was limited evidence available and this could not be conclusively determined. In addition, it could not be established if environmental or ground support activities contributed to the event. Likewise, the reason for the three earlier similar incidences of 3/4 inch acoustic panels failing on Trent 700 engines on other aircraft could not be established with certainty. For all four events, the panels failed at largely different flight hours and cycles, therefore, nil conclusions could be drawn with regard to operational characteristics.

In comparison, tests conducted on the adjacent acoustic panel manufactured and fitted about the same time as the failed panel, did not identify any deficiencies in design, build or significant in-service deterioration. Therefore, it was reasonable to conclude that the manufacturing or design process likely did not contribute to the failure.

In response to the earlier incidents, Rolls-Royce initiated a number of actions including the introduction of a tap test inspection to identify potential delamination of the brochier from the honeycomb. The ATSB had considered if these inspections were ineffective, incorrectly performed or did not address the root cause of the acoustic panel failure. The tap test had been conducted on the failed panel about 3 months prior and nil delamination was detected. However, as damage was identified and repaired on the adjacent intact panel, the inspection technique was considered likely effective.

Rolls-Royce also introduced a product improvement, which strengthened the panels from being constructed from a 3/4 inch to a 3/8 inch honeycomb cell (3.0 lbs/ft3 density honeycomb core), effectively doubling the bond joint between the honeycomb and brochier. To date, there have been nil reports of 3/8 inch panels failing.

Based on the available evidence, Rolls-Royce postulated that the most likely cause of the acoustic panel failure was a localised disbond between the honeycomb core and facing sheet. It was likely that the disbond grew to a critical size, greater than 22x22 inch area resulting in the panel collapsing at high engine power during take-off.

However, the reason for the local disbonding could not be established. Nevertheless, contributing factors such as maintenance activities, ground handling and foreign object debris damage could not be discounted as possible initiation source of the likely disbond.

Incident Facts

Date of incident

Jun 11, 2017

Classification

Incident

Airline

China Eastern Airlines

Flight number

MU-736

Departure

Sydney, Australia

Destination

Shanghai Pudong, China

Aircraft Registration

B-6099

Aircraft Type

Airbus A330-200

ICAO Type Designator

A332

This article is published under license from Avherald.com. © of text by Avherald.com.

Article source

You can read 2 more free articles without a subscription.

Subscribe now and continue reading without any limits!

Read unlimited articles and receive our daily update briefing. Gain better insights into what is happening in commercial aviation safety.

Send tip

Support AeroInside by sending a small tip amount.

Related articles

China Eastern B738 near Guangzhou on Mar 21st 2022, lost altitude and impacted terrain

A China Eastern Boeing 737-800, registration B-1791 performing flight MU-5735 from Kunming to Guangzhou (China) with 123 passengers and 9 crew on…

China Eastern A332 at Shanghai on Dec 9th 2023, could not retract landing gear

A China Eastern Airbus A330-200, registration B-6538 performing flight MU-533 from Shanghai Pudong (China) to London Heathrow,EN (UK), was climbing…

China Eastern A333 near Xiamen on Dec 3rd 2023, uncontained engine failure

A China Eastern Airbus A330-300, registration B-8970 performing flight MU-721 from Shanghai Hongquiao to Hong Kong (China), was enroute at 10400…

China Eastern A332 near Wuhan on Aug 14th 2023, power bank began to smoke

A China Eastern Airlines Airbus A330-200, registration B-5930 performing flight MU-6958 from Lhasa to Shanghai Pudong (China), was enroute at 10,700…

China Eastern A321 at Hong Kong on May 24th 2017, runway excursion on landing

A China Eastern Airbus A321-200, registration B-6366 performing flight MU-765 from Nanjing to Hong Kong (China) with 132 passengers and 9 crew, was…

Newest articles

Dana MD82 at Lagos on Apr 23rd 2024, runway excursion

A Dana Air McDonnell Douglas MD-82, registration 5N-BKI performing flight 9J-352 from Abuja to Lagos (Nigeria) with 83 people on board, landed on…

THY B773 at Tokyo on Apr 20th 2024, approached wrong runway

A THY Turkish Airlines Boeing 777-300, registration TC-JJT performing flight TK-198 from Istanbul (Turkey) to Tokyo Haneda (Japan), was cleared to…

Subscribe today

Are you researching aviation incidents? Get access to AeroInside Insights, unlimited read access and receive the daily newsletter.

Pick your plan and subscribePartner

A new way to document and demonstrate airworthiness compliance and aircraft value. Find out more.

ELITE Simulation Solutions is a leading global provider of Flight Simulation Training Devices, IFR training software as well as flight controls and related services. Find out more.

Your regulation partner, specialists in aviation safety and compliance; providing training, auditing, and consultancy services. Find out more.

AeroInside Blog

Popular aircraft

Airbus A320Boeing 737-800

Boeing 737-800 MAX

Popular airlines

American AirlinesUnited

Delta

Air Canada

Lufthansa

British Airways