United B772 at Denver on Feb 20th 2021, engine inlet separates from engine, engine fire

Last Update: September 8, 2023 / 16:24:01 GMT/Zulu time

Incident Facts

Date of incident

Feb 20, 2021

Classification

Incident

Airline

United

Flight number

UA-328

Departure

Denver, United States

Destination

Honolulu, United States

Aircraft Registration

N772UA

Aircraft Type

Boeing 777-200

ICAO Type Designator

B772

Airport ICAO Code

KDEN

A replacement Boeing 777-200 registration N773UA reached Honolulu as flight UA-3025 with a delay of 6 hours.

Beyond the damage to the right hand engine itself the aircraft received a puncture of the right hand wing root fairing below the right hand wing.

The engine inlet fell into the neighbourhood of Broomfield,CO, located about 16nm west of Denver near 13th and Elmwood Street, the debris also struck through the roof of an adjacent house.

Broomfield police reported that although debris impacted the neighbourhood and damaged a number of homes, there were no injuries on the ground. The debris field expands over a nautical mile.

Ground observers reported hearing the sound of an explosion like bang, smoke and saw the debris falling down. The aircraft continued flying.

Another ground observer, John Sloan (also see reader comments below), reported: "I was walking home from lunch and heard a boom. I thought it might be a fighter going supersonic, but when I looked up I noticed a 2-engine commercial plane on a roughly west-bound heading. There was a fairly low cloud deck (maybe a few thousand feet) and he was just below it, so it was difficult to discern visual details, but I suddenly heard his engine noise go from silent to moderately loud (that might have been what made me notice him) - not sure if he applied power or if it was a trick of acoustics. Looking behind him, there was what looked like a large black puff of smoke (but it might have just been clouds). Similarly, it looked like there was a thin trail of black smoke coming from the starboard engine, but again, it was hard to make out and might have just been a contrail. As he passed overhead the smoke trail seemed to go away. Once past me, he might have begun a turn to port (back towards the airport), but he vanished into the clouds so it was hard to tell. It looked like the aircraft was under control the whole time it was visible." The following day John Sloan wrote in his reader comment: "Two things: 1) I was giving Simon a heads up to look for a report out of DEN - if it was anything, I thought it was just something like a (big) compressor stall. That was why so many caveats were there - I wasn't sure at the time that the aircraft had had a problem. I didn't realize it was going to be widely reported until my mother texted me a couple of hours later asking if any of the plane parts came down close to me. 2) Something I omitted that I should have put in: After I got home I imagined how many thumb-widths at arm's length it would take to occlude it (from memory), and plugged that into similar triangles and the length of a 737 (didn't realize it was a 777) to get an estimated altitude and got 2-4 thousand meters. I thought the cloud deck was only 2000 feet AGL or so, so I didn't believe the numbers. I did change "a couple" to "a few" though. Turns out it was ~8000 feet AGL. I should have believed more in the math!"

The FAA reported the aircraft experienced a right hand engine failure and is aware of debris on the ground along the flight path of the aircraft. The FAA as well as the NTSB have opened investigations, the NTSB is leading the investigations.

On Feb 21st 2021 the FAA Administrator stated that an Emergency Airworthiness Directive (EAD) is to be prepared, that requires immediate or stepped up inspections of Boeing 777 aircraft with certain PW4000 engines likely resulting in a number of aircraft being removed from service. The Administrator said: "We reviewed all available safety data following yesterday's incident. Based on the initial information, we concluded that the inspection interval should be stepped up for the hollow fan blades that are unique to this model of engine used solely on Boeing 777 airplanes."

Late Feb 23rd 2021 the FAA released their Emergency Airworthiness Directive EAD-2021-05-51 for all PW4074, PW4074D, PW4077, PW4077D, PW4084D, PW4090, and PW4090-3 model turbofan engines. The FAA argues: "This emergency AD was prompted by the in-flight failure of a 1st-stage low-pressure compressor (LPC) blade on a PW4077 model turbofan engine resulting in an engine fire during flight. This condition, if not addressed, could result in 1st-stage LPC blade release, damage to the engine, and damage to the airplane." The EAD requires operators to "Before further flight, perform a thermal acoustic image (TAI) inspection of the 1st-stage LPC blades for cracks using a method approved by the FAA." If any 1st-stage LPC blade fails the inspection, remove the blade from service and replace with a part eligible for installation before further flight.

The NTSB stated they have opened an investigation into the occurrence, "Denver-based NTSB investigators are responding".

On Feb 21st 2021 the NTSB reported a senior NTSB investigator as well as three further NTSB investigators, all four based in the Denver area, responded and began working with local law enforcement officials to coordinate the recovery of components that separated from the engine and fell into residential areas. The NTSB investigator in charge along with a powerplant specialist travelled from Washington to Denver on Feb 21st 2021. The NTSB wrote:

The initial examination of the airplane indicated most of the damage was confined to the number 2 engine; the airplane sustained minor damage. The examination and documentation of the airplane is ongoing.

The initial examination of the Pratt & Whitney PW4077 engine revealed:

- The inlet and cowling separated from the engine

- Two fan blades were fractured:

+ One fan blade was fractured near the root

+ An adjacent fan blade was fractured about mid-span

+ A portion of one blade was imbedded in the containment ring

+ The remainder of the fan blades exhibited damage to the tips and leading edges

Investigators continue to examine the engine, airplane and the photographs and video taken by passengers aboard United flight 328.

The cockpit voice recorder and flight data recorder were transported to the NTSB laboratory in Washington where each will be downloaded and analyzed.

On Feb 22nd 2021 the NTSB reported in a virtual media briefing that the right hand engine suffered the failure of one fan blade at about 12,500 feet MSL, the fractured blade caused an overload to the neighboured blade which fractured about mid span. Following the failure the crew pulled the fire handle and discharged both fire bottles. Fuel was turned off. The NTSB is looking into what caused the fire to continue. There was additional damage to a composite fairing, the damage was not structural. One of the blades was found in the soccer field on the ground. Following landing the crew assessed no emergency evacuation was necessary. Metal fatigue played a role and is being looked at. The engine's maintenance history is being reviewed. Additional debris was found Monday morning (Feb 22nd 2021) in Arvada about 20nm westsouthwest of Denver Airport. First inspections of the engine do not suggest that anything pierced the containment ring and engine case. At this point the NTSB does not consider the engine failure as uncontained, the containment ring did contain the fractured fan blades, the failure thus was contained.

On Feb 21st 2021 United, Japan Airlines and All Nippon Airways grounded their active Boeing 777 aircraft equipped with PW-40xx engines.

On Feb 13th 2018 a fractured and separated fan blade had caused the engine inlet and cowl to separate from the right hand engine of B772 registration N773UA, see Incident: United B772 over Pacific on Feb 13th 2018, fan blade, engine cowl and inlet separated in flight, blade debris impacted fuselage.

On Mar 5th 2021 the NTSB released an investigation update stating:

Facts gathered to date in the investigation, and provided in the update, include:

- Initial examination of the right engine fire damage found it was primarily contained to the engine's accessory components, thrust reverser skin, and composite honeycomb structure of the inboard and outboard thrust reversers.

- The spar valve, which stops fuel flow to the engine when the fire switch is pulled in the cockpit, was found closed – there was no evidence of a fuel-fed fire.

- Initial examination of the right engine fan revealed the spinner and spinner cap were in place and appeared undamaged.

- All fan blade roots were in place in the fan hub, two blades were fractured.

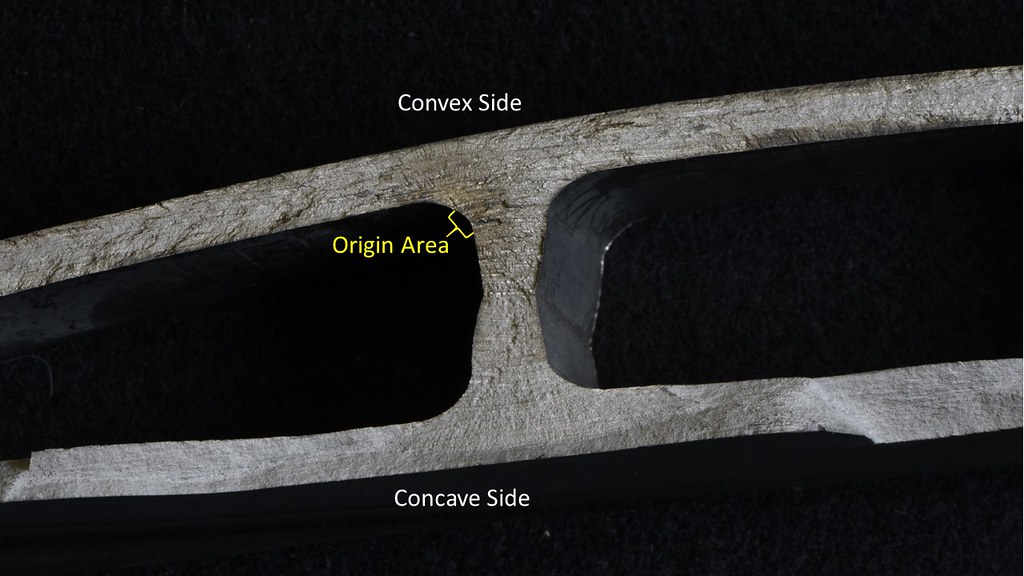

- One fan blade was fractured 7.5 inches above the base at the trailing edge. The fracture surface was consistent with fatigue.

- The second fractured blade exhibited indications of overload failure, consistent with secondary damage.

- Initial review of maintenance and inspection data for the blade with the fatigue fracture, revealed it had experienced 2,979 cycles since its last inspection. This blade underwent thermal acoustic image inspections in 2014 and 2016. Inspection data collected from the 2016 inspection was examined again in 2018 because of a Feb. 13, 2018, incident involving a Boeing 777 with Pratt & Whitney PW4077 engines.

The engine fan blade with the fractures consistent with fatigue was sent to the metallurgical laboratory at Pratt & Whitney for further examinations led by a senior NTSB metallurgist. Preliminary findings from the scanning electron microscope examination identified multiple fatigue fracture origins on the interior surface of a cavity within the blade. Efforts to further characterize the fracture surface, including identifying the primary origin and counting striations, are ongoing. Additional work is underway to further characterize secondary cracks identified through fluorescent penetrant inspection. The NTSB metallurgy group also plans to analyze the blade's chemical composition and microstructure near the fracture surface.

ON Sep 8th 2023 the NTSB released their final report and investigation docket concluding the probable cause of the incident was:

The fatigue failure of the right engine fan blade.

Contributing to the fan blade failure was the inadequate inspection of the blades, which failed to identify low-level indications of cracking, and the insufficient frequency of the manufacturer’s inspection intervals, which permitted the low-level crack indications to propagate undetected and ultimately resulted in the fatigue failure.

Contributing to the severity of the engine damage following the fan blade failure was the design and testing of the engine inlet, which failed to ensure that the inlet could adequately dissipate the energy of, and therefore limit further damage from, an in-flight fan blade out event.

Contributing to the severity of the engine fire was the failure of the “K” flange following the fan blade out, which allowed hot ignition gases to enter the nacelle and imparted damage to several components that fed flammable fluids to the nacelle, which allowed the fire to propagate past the undercowl area and into the thrust reversers, where it could not be extinguished.

The NTSB analysed:

United Airlines flight 328 was climbing through 12,500 ft mean sea level about 5 minutes after departure from Denver International Airport (DEN), Denver, Colorado, when the right engine, a Pratt & Whitney PW4077, sustained a full-length fan blade separation, or fan blade out (FBO) event. This resulted in the subsequent separation of the engine inlet lip skin, fan cowl support beam, and components of the inlet, fan cowls, and thrust reversers (TRs), as well as an engine fire. The flight crew declared an emergency and landed the airplane without incident at the departure airport about 24 minutes after takeoff. There were no injuries to the passengers or crew, and no ground injuries due to debris; however, a vehicle and a residence sustained damage when impacted by the inlet lip skin and fan cowl support beam, respectively.

Fan Blade Impact Damage

Examination of the engine revealed that the separated fan blade and other fan debris impacted the fan case, which successfully contained the fan blade fragments. Damage to the nacelle inner and outer barrels was observed, and a postaccident evaluation indicated that the displacement wave of the impact resulted in a deflection of the fan case and contact with the nacelle doors and hinges, which subsequently resulted in the failure of the inlet aft bulkhead and the fan cowl support beam. The failure of the bulkhead, along with the damage to the inner and outer barrels, allowed these structures, as well as the inlet lip skin, to separate from the engine.

Following the separation of the inlet, air loads resulted in the separation of the fan cowls and the fan cowl support beam. Simulation studies indicated that the carbon fiber reinforced plastic (CFRP) honeycomb structure of the event engine inlet and inlet aft bulkhead was unable to dissipate and redistribute the energy of the loads imposed by the FBO event in the same manner as the aluminum structure inlet that was used during certification tests.

Separation of the inlet and fan cowls due to an FBO event is not allowed under certification standards, and following this event, Boeing developed modifications to the inlet to ensure that inlets and fan cowls remain in place during an FBO event that may damage the aft bulkhead, inner barrel, or outer barrel and modifications to add strength and ductility to the inlet by incorporating additional metallic structure. Boeing also developed procedures for inspection and repair for moisture ingression damage to the fan cowls, which can degrade the strength of the cowls. These modifications were subsequently mandated by Federal Aviation Administration (FAA) Airworthiness Directives (AD) 2022-06-10 and 2022-06-11, effective April 15, 2022. Additional modifications are expected to the fan cowl.

This event was the fourth in-service FBO event due to fatigue cracking recorded for PW4000- powered 777 airplanes and resulted in the most nacelle damage of the four events. In the first event in 2010, approximately 50 percent of the blade airfoil was released. Full-span separations occurred in 2018, 2021, and during this event.

Engine Fire Propagation

Seconds after the FBO event, the flight crew received a right engine fire warning. The crew completed the engine fire checklist, which included activating the fire switch and discharging both engine fire extinguishing bottles; however, the fire was not arrested and continued to propagate through the engine for the remainder of the flight due to damage the engine sustained during the fan blade out event. Although the cockpit fire warning light extinguished shortly before landing, this was likely the result of thermal damage to the engine fire detection system.

The engine fire propagated as the result of several cascading failures following the FBO event. The engine core was subjected to high dynamic loads due to the energy of the initial blade release; the fan blade rubbing against the case, which created rotating torsion loads through the engine core structure; and the continued fan shaft imbalance during the engine run-down, which created rotating bending loads through the core structure. The loading associated with the high dynamic activity of the attached main gearbox (MGB) ultimately resulted in the failure of the “K” flange bolts that attached the MGB to the engine. The remaining “K” flange bolts then fractured, resulting in the total separation of the “K” flange, which allowed hot, compressed gases to escape the engine core and provided an ignition source in the engine nacelle.

As the “K” flange was part of the MGB support structure, the failure of the flange also allowed the MGB to rotate and the MGB-mounted servo fuel heater to contact the engine core-mounted fuel oil cooler. As a result of this contact, a high-pressure fuel cavity within the servo fuel heater was fractured open, releasing high-pressure fuel into the nacelle, where it was ignited by the hot, compressed gases that escaped through the “K” flange separation.

Pratt & Whitney is evaluating actions to improve the strength of the “K” flange and expects hardware to be available in 2025.

The fire spread to the TR lower bifurcation area, burned away the support structure for the nacelle drain access door, and exited the lower aft TR area. The undercowl fire melted the aluminum latch beams at the lower end of each TR and through the TR inner wall and translating sleeves. One of the last components to separate from the airplane was a section of the outboard TR translating sleeve, which was located about 30 miles southeast of the debris associated with the initial FBO event. The burn-through of the TR lower bifurcation area likely occurred within about six to nine minutes of the initial FBO event, though certification standards required that materials in this area withstand fire for a minimum of 15 minutes.

Examination of the engine’s fire suppression system revealed that the engine driven hydraulic pump supply shutoff valve failed to close as designed upon the crew’s activation of the engine fire handle due to silicone lubricant contamination of electrical contact components in the valve’s DC motor. The failure of the valve to close allowed a limited amount of hydraulic fluid to leak into the engine compartment and feed the undercowl fire.

FAA AD 2022-06-10 and 2022-06-11 required installation of debris shields on the TR inner wall lower bifurcation area, as well as repeated functional checks of the engine driven hydraulic pump supply shutoff valves to ensure proper operation in response to fire switch activation.

Fan Blade Fatigue Failure and Inspection Process

The separated fan blade was fractured transversely across the chord of the airfoil near the fan hub fairing as the result of a fatigue crack, which originated at the surface of an internal radius in a hollow cavity within the blade. The event blade had accumulated 2,979 cycles since overhaul; at the time of the event, overhaul inspection was required every 6,500 cycles. As part of the overhaul, blades were inspected for both external and internal cracks using a proprietary thermal acoustic imaging (TAI) process.

The most recent TAI inspection of the event fan blade occurred about five years before the event, in 2016. Inspection imagery revealed multiple low-level indications, two of which were in the fatigue crack origin area, that were reviewed further and interpreted as being generated by camera sensor noise or loose contamination within the cavity. Given the observed indications and the inspection criteria in place at the time, the blade should have received a second TAI inspection, or the images should have undergone a team review; however, there was no record that either of these occurred, and the blade was approved for continued service.

Following an FBO event in 2018 involving another PW4077 engine, the data from the 2016 inspection of the blade involved in this event were reviewed again; once more, the indications were not identified as anomalous and the blade continued in service. Two of the low-level indications identified during the 2016 TAI inspection were likely associated with the fatigue crack that grew to result in the blade failure.

The accident blade had accumulated 15,262 cycles since new, which was less than one quarter of the expected life for a nominal blade, and only 2,979 cycles since its last overhaul, less than half the prescribed inspection interval at the time. Metallurgical examination identified two conditions which contributed to the reduced fatigue life of the accident blade: a surface carbon contamination; and a geometric discontinuity that occurred during manufacturing. In assessing fatigue life of this blade relative to the nominal expectation, the reduced fatigue capability from the surface carbon contamination accounted for approximately 2/3 of the difference, and the increased stress from the geometric discontinuity accounted for approximately 1/3 of the difference.

Following this event, Pratt & Whitney performed an immediate TAI inspection of the entire fleet before the next flight and issued a service bulletin introducing ultrasonic testing (UT) blade inspections to occur both immediately and at regular intervals. Additionally, the frequency of required TAI inspections was increased from every 6,500 cycles to every 1,000 cycles. The increased inspection interval and the immediate TAI inspection were made mandatory on April 15, 2022, when the FAA issued AD 2022-06-09. Additionally, the new UT inspection that was developed by Pratt & Whitney for the flowpath and midspan areas has shown a capability to detect small cracks that are below the threshold of detectability for the TAI inspection. The blades are now inspected by UT every 275 cycles.

Examination of the crack in this event and previous fan blades failure events have shown the growth rates of the fatigue crack, from detectable size to full-wall penetration, are relatively stable and predictable in each case, since the sources for premature fatigue initiation are surface related and do not have a significant impact on growth through the thickness of the blade. The increased TAI inspection interval and the new UT inspections should provide multiple opportunities to detect cracks in the high-stress areas.

Related NOTAM (Japan FIR):

Q0396/21 NOTAMN

Q) RJJJ/QAFXX/IV/NBO/E/000/999/3310N14118E999

A) RJJJ B) 2102211257 C) 2105210830 EST

E) ALL AIR CARRIERS OPR(TAKING-OFF/LANDING AND OVER FLT) WI THE

TERRITORY OF JAPAN ARE REQUESTED TO AVOID USING BOEING 777 EQUIPPED

WITH PW4000 SERIES ENGINES UNTIL FURTHER NOTICE

Metars:

KDEN 202053Z 36019KT 10SM BKN100 BKN200 11/M04 A2967 RMK AO2 SLP031 T01111039 56036=

KDEN 201953Z 18005KT 10SM FEW085 SCT130 SCT200 13/M09 A2970 RMK AO2 SLP040 T01331094=

KDEN 201853Z VRB04KT 10SM FEW090 FEW200 12/M09 A2973 RMK AO2 PRESFR SLP052 SHSN OMTNS DSNT W-NW T01171089=

KDEN 201753Z 21015KT 10SM FEW070 FEW100 FEW200 11/M07 A2979 RMK AO2 SLP077 T01111072 10111 21044 58018=

KDEN 201653Z 21017KT 10SM FEW070 FEW100 FEW200 09/M07 A2982 RMK AO2 SLP091 T00891072=

KDEN 201553Z 21015G23KT 10SM FEW070 FEW100 FEW200 06/M07 A2984 RMK AO2 PK WND 20026/1513 SLP103 T00611072=

Aircraft Registration Data

Incident Facts

Date of incident

Feb 20, 2021

Classification

Incident

Airline

United

Flight number

UA-328

Departure

Denver, United States

Destination

Honolulu, United States

Aircraft Registration

N772UA

Aircraft Type

Boeing 777-200

ICAO Type Designator

B772

Airport ICAO Code

KDEN

Videos

Photos

This article is published under license from Avherald.com. © of text by Avherald.com.

Article source

You can read 2 more free articles without a subscription.

Subscribe now and continue reading without any limits!

Read unlimited articles and receive our daily update briefing. Gain better insights into what is happening in commercial aviation safety.

Send tip

Support AeroInside by sending a small tip amount.

Related articles

United B772 near Shannon on Apr 16th 2012, medical emergency

A United Airlines Boeing 777-200, registration N772UA performing flight UA-941 from Frankfurt/Main (Germany) to Chicago O'Hare,IL (USA), was enroute…

United B739 at Austin on May 5th 2024, flaps problem

A United Boeing 737-900, registration N39463 performing flight UA-381 from Washington Dulles,DC to Austin,TX (USA), was on final approach to Austin's…

United B39M at Orlando on Apr 26th 2024, runway incursion forces rejected takeoff

A United Boeing 737-9 MAX, registration N37540 performing flight UA-1929 from Newark,NJ to Orlando,FL (USA), had landed on Orlando's runway 18R and…

United B763 near Providence on Apr 22nd 2024, suspected fuel leak

A United Boeing 767-300, registration N644UA performing flight UA-108 from Washington Dulles,DC (USA) to Munich (Germany), was enroute at FL330 about…

United B789 near San Francisco on Apr 19th 2024, cargo smoke indication

A United Boeing 787-9, registration N15969 performing flight UA-801 from Los Angeles,CA (USA) to Hong Kong (China), was enroute at FL340 about 30nm…

United B753 enroute on Apr 10th 2024, Rockies' coach in captain's seat

A United Boeing 757-300, registration N73860 performing charter flight UA-3779 from Denver,CO (USA) to Toronto,ON (Canada) with the Colorado Rockies…

Newest articles

Serve Cargo B733 at Kinshasa on May 5th 2024, runway excursion after engine failure

A Serve Air Cargo Boeing 737-300 freighter, registration 9S-AKK performing a flight from an unknown point of origin to Kinshasa N'djili (DR Congo),…

American A319 at Washington on May 2nd 2024, engine issue

An American Airlines Airbus A319-100, registration N716UW performing flight AA-1263 from Washington National,DC to Chicago O'Hare,IL (USA), was…

Subscribe today

Are you researching aviation incidents? Get access to AeroInside Insights, unlimited read access and receive the daily newsletter.

Pick your plan and subscribePartner

A new way to document and demonstrate airworthiness compliance and aircraft value. Find out more.

ELITE Simulation Solutions is a leading global provider of Flight Simulation Training Devices, IFR training software as well as flight controls and related services. Find out more.

Your regulation partner, specialists in aviation safety and compliance; providing training, auditing, and consultancy services. Find out more.

AeroInside Blog

Popular aircraft

Airbus A320Boeing 737-800

Boeing 737-800 MAX

Popular airlines

American AirlinesUnited

Delta

Air Canada

Lufthansa

British Airways